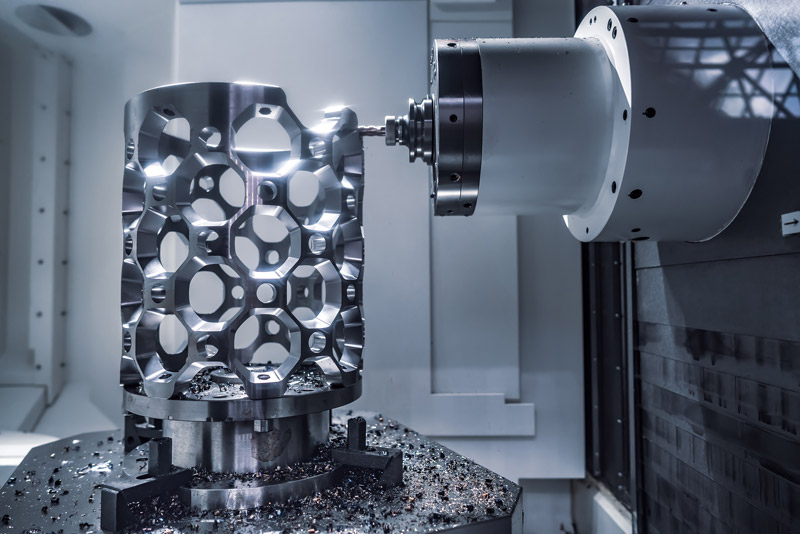

CNC milling

Milling carried out with three and four-axis vertical and horizontal CNC machining centres, single and multi-pallet.

Milling is a subtractive process, which therefore takes place by chip removal, allowing to obtain a vast range of details or semi-finished products starting from a larger unfinished piece. It is one of the most widespread mechanical processes carried out on an industrial level.

Mecal srl carries out CNC milling, which stands for “Computer Numerical Control”, i.e. through a category of automatic machines controlled by a computer which uses G-code commands to model the material starting from a file of the model to be created.

Suitable tools are mounted on the appropriate spindle of the machine depending on the milling operations to be performed. The CNC machine has three, four or five axes of motion. The tools are moved along these axes following the CNC program instructions. The combination of movements along the axes allows the machine to cut, drill or shape the material according to the drawing specifications.

MECAL SRL USES 3, 4, AND 5-AXIS CNC MACHINES FOR ITS MILLING.

WE HAVE PALLETISED MACHINING CENTRES:

HORIZONTAL: MAXIMUM MACHINED PIECE VOLUME 500X500X600MM

VERTICAL: MAXIMUM MACHINED PIECE VOLUME 1000X500X400MM

Types of CNC milling

There are different types of cutters for ferrous metals, steel, aluminium: there are specific cutters, able to ensure the best possible result, for each material and for each process.

The cutters are divided according to use and conformation:

- Helical cutters

- Staggered tooth cutter

- Double angle cutters

- Flat cutters

- End mill cutters

- Chamfer cutters

- Front cutters

WHAT IS CNC MILLING?

Milling is carried out using a tool with multiple lateral cutting edges called a milling cutter, which is made of carbide steel and which can have a cylindrical, conical, spherical or hemispherical shape, but also an isosceles trapezoidal cross-section (truncated cone). The cutter is set in rotation by means of an electric spindle with rotation up to 18,000 rpm, driven by an electric motor.

WHAT IS CNC MILLING USED FOR?

Through the milling process it is possible to remove material, which is then useful for obtaining various surfaces. Milling lets you work many metal components: it is used to obtain pieces in aluminium, stainless steel and other metal alloys. The machine rapidly mills parts from the block of material using a subtractive machining process with 3, 4 or 5-axis milling.